Promotion of Health and Safety

The Shindengen Group recognizes the importance of promoting health and safety, and is working to constantly improve occupational health and safety and to provide safe and healthy working environments for its employees. The Central Health and Safety Committee is chaired by the officer in charge of safety promotion and, in accordance with the Occupational Health and Safety Policy, strives to ensure the safety of all employees, maintain and promote their physical and mental health, and create a comfortable working environment.

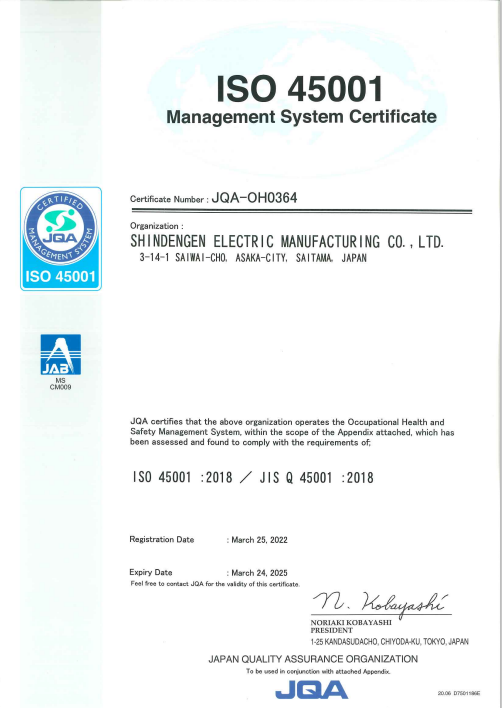

Acquisition of ISO 45001 Certification

The Asaka Office of Shindengen Electric Manufacturing Co., Ltd. (Asaka City, Saitama Prefecture), Okabe Shindengen Co., Ltd. (Fukaya City, Saitama Prefecture), and Shindengen Thailand (the Kingdom of Thailand) have each obtained ISO 45001 certification, which is the international standard for occupational health and safety management systems. ISO 45001 defines the construction and operation of systems that provide safe and healthy workplaces and prevent injuries and diseases related to worker labor. Since its publication, the standard has spread around the world. The Shindengen Group is striving to continually improve occupational health and safety, upgrades work environments focused on employee health and safety, enhances productivity, and ensures business continuity.

Traffic Safety Activity

Shindengen Electric Manufacturing Co., Ltd.’s Asaka Office has participated in the “Cycling Etiquette Improvement and Safety Promotion Company” project designated by Saitama Prefectural Police since April 2023. The goal of the Cycling Etiquette Improvement and Safety Promotion Company project is for companies to voluntarily engage in activities concerning the safe use of bicycles in order to help prevent bicycle accidents. While the number of bicycle commuters is increasing due to greater health awareness, we will continue to educate and raise awareness among our employees to improve cycling etiquette.

During Traffic Safety Week at Higashine Shindengen Co., Ltd., we provide crossing guards at intersections near the plant to guide pedestrians and to participate in traffic safety campaigns.

As an excellent organization addressing traffic safety problems, Lumphun Shindengen received the Prime Minister Road Safety Award from Thailand’s Prime Minister in December 2021. We are continuing our traffic safety initiatives in FY 2022 as well, including by conducting free inspections for our employees' cars and motorcycles and safe driving lessons with the cooperation of local companies.

-

-

-

Distributing flyers with Asaka Police Station

(Asaka Office, Shindengen Electric Manufacturing Co., Ltd.)

-

-

-

-

Driver safety education and free motorcycle inspections

(Lumphun Shindengen)

-

Risk Assessment Training

Shindengen Electric Manufacturing Co., Ltd., has established workplace health and safety committees in each of its departments, and provides risk assessment training to the committee members. We are working to prevent workplace accidents and disasters by identifying potential risks and hazards in the workplace and by implementing controls to prevent, eliminate, and mitigate these risks. In FY 2023, there were no fatal accidents or serious occupational accidents resulting in permanent disability.

Products that Contribute to Safety

AEC-Q101 compliant high withstand voltage 900V MOSFET—Contributing to improved reliability in vehicle device applications—

The Shindengen Group develops, designs, produces, and sells environmentally friendly products in line with its corporate mission. While these products have a wide variety of applications in areas ranging from mobility, the environment and energy, industrial machinery, information and communication, and home appliances, they are also used in areas that contribute to human safety by protecting lives and livelihoods. In recent years, many MOSFETs have been installed in environmentally friendly vehicles (xEVs), which are now spreading rapidly due to stricter regulations to combat global warming. There is particularly strong demand for high-voltage and highly reliable MOSFETs used as switching elements in sub-power sources that convert power from 400 V-class high-voltage batteries to lower voltages, and those used in circuits that rapidly discharge accumulated charge in electrolytic capacitors when turned on. To meet these needs, we have added two new models to our “VX3 series” lineup of automotive high withstand voltage MOSFETs, namely the 900V 1A “P1B90VX3K” and the 900V 2A “P2B90VX3K.” This product features a revamped internal structure delivering a guaranteed 2kV HBM rating and 200V MM rating, and meeting the high-tolerance ESD requirements of in-vehicle devices. This functionality contributes to the improved reliability of in-vehicle devices. Shindengen Electric Manufacturing Co., Ltd. will continue to meet the demand for high withstand voltage products in the in-vehicle device market.

-

-

-

High withstand voltage MOSFET for automotive use

VX3 Series

-

Improving Workplace Security & Safety and Comfort

Leveraging the advantage of its office environment having acquired CASBEE Wellness Office Certification Rank S, Shindengen aims to enhance security and safety as well as environments in which it is easy to work.

*CASBEE Wellness Office is a tool for evaluating initiatives, performance, and building design to support maintaining and increasing the health and comfort of building users. It evaluates not only elements that directly affect the health and comfort of workers within the building but also elements that help enhance intellectual productivity and performance related to security and safety.

-

-

-

4F Atrium, Asaka Office

(Shindengen Electric Manufacturing Co., Ltd.)

-

-

-

-

CASBEE Wellness Office Certification

(Shindengen Electric Manufacturing Co., Ltd.)

-