The Shindengen Group is committed to reducing its environmental footprint. We focus on managing activities that address global warming, the proper use and disposal of chemicals, safe waste disposal, and water-use reduction as well as protecting biodiversity and shrinking our environmental footprint.

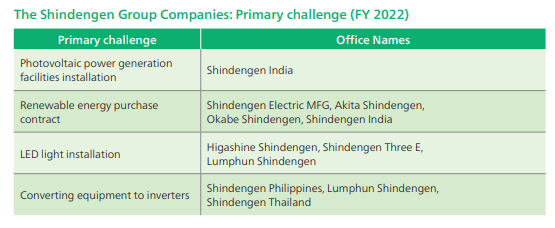

The following introduces our FY 2022 main activities, including practical case studies.

Reduction of carbon dioxide emission volume

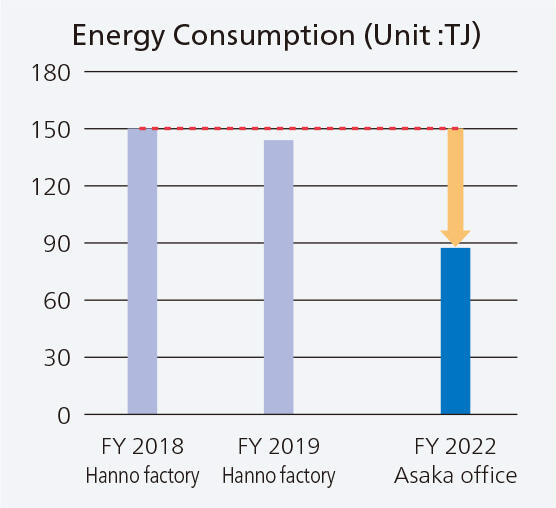

The Shindengen Group is endeavoring to reduce its CO2 emissions to fulfill the FY 2030 environmental targets it announced at the same time as its Environmental Vision 2050. The Shindengen Group in Japan participates in the Carbon Neutrality Action Plan formulated and promoted by the electric and electronic machine industries as a voluntary action plan, and to improve its energy intensity improvement rate by a yearly average of 1% or more and reduce its CO2 emissions by 46% compared to FY 2013, it is engaged in activities to improve the energy efficiency of its production processes and improve equipment, and it undertakes various measures to reduce CO2 emissions in its business activities. Amidst such efforts, Shindengen Electric Manufacturing Co., Ltd. aims to reduce its CO2 emissions by 46% in FY 2030 compared to FY 2013, and from October 2022, it greatly increased the percentage of non-fossil certificate CO2-free power supplied to the Asaka Office from the original 30% to 100%. As a ZEB Ready building, in addition to its energy-saving performance (a reduction of at least 50% in baseline energy consumption) the Asaka Office has achieved the feat of changing all of its power to CO2-free power and greatly reducing its CO2 emissions. Furthermore, Okabe Shindengen has introduced non-fossil certificate CO2-free power equivalent to 50% of its electric power used, and Akita Shindengen, Higashine Shindengen and Shindengen Three E also plan to follow suit in introducing CO2-free power. The CO2 emission reduction effect of domestic Group companies in FY 2022 was equivalent to approximately 1,550t-CO2 thanks to the introduction of CO2-free power. For overseas Group companies, Shindengen India is striving to reduce CO2 emissions by installing solar power generating equipment on top of its roof. Additionally, all of the Shindengen Group companies inside and outside Japan are engaged in energy-saving activities to reduce their CO2 emissions. These include upgrading to energy-saving equipment such as LED lighting, improving production equipment and processes, and increasing air conditioning efficiency. This is in addition to the efficient operation of factory equipment through moves such as turning off the power on unused equipment through the diligent power-saving efforts of employees.

*The Asaka Office acquired ZEB Ready certification as an advanced building approaching ZEB (Net Zero Energy Building), the highest rank in the Building-Housing Energy-Efficiency Labeling System (BELS).

An Example of Reducing CO2 by Changing the Transportation Method

Starting in FY 2022, Shindengen Electric Manufacturing Co., Ltd. has been working on “Green Logistics,” a joint delivery service in collaboration with other companies in the same industry who have locations in the same Saitama Prefecture. Although other companies in the same industry are business rivals, we have a common point in that our delivery destinations are close, so our interests are aligned on the subject of more efficient transportation. We therefore started a joint delivery scheme where trucks go around delivery destinations with the products from our companies mixed and loaded. From June 2022 to March 2023, they saved about 830km in distance travelled, roughly equal to the distance from Tokyo to Kyushu.

FY 2022 Asaka Office (April 2021 start) Energy Use Reduction Effects

The Shindengen Group Companies: Primary challenge(FY2022)

Contributing By Providing Environmentally Friendly Products

Aiming to achieve decarbonization and sustainability across society, as targeted by the Paris Agreement, the Shindengen Group provides environmentally friendly products as a proactive way of reducing greenhouse gas emissions during product use and solving issues in line with the international sustainable development goals (SDGs) initiative. The Group agrees with measures promoted by local communities to mitigate and adapt to climate change effects and proactively supports related activities.

Greenhouse Gas Emissions (Scope 1, Scope 2, Scope 3)

Shindengen Electric Manufacturing Co., Ltd. calculates the GHG protocol's Scope 1, Scope 2, and Scope 3 emissions based on greenhouse gas emissions-related data collected from the value chain.

Initiatives to Reduce Plastic

The Shindengen Group in Japan aims to be environmentally friendly by replacing or reducing the use of plastic, and each company has set specific targets for reducing plastics, which it is working towards. Shindengen Electric Manufacturing Co., Ltd. held an internal briefing session mainly on the Act on Promotion of Resource Circulation for Plastics which went into effect in 2022. This enabled them to align the awareness of all employees on plastics and obtain understanding for future initiatives. Meanwhile, individual Group companies in Japan have set targets that suit them, such as reducing the amount of packaging, selecting recycling operators to implement continued recycling, and increasing the recycling rate through improved sorting.

Lumphun Shindengen Awarded ECO FACTORY Certification

Lumphun Shindengen received ECO FACTORY certification in recognition of its participation in SDGs schemes organized by the Ministry of Industry in Thailand and the industrial park secretariat, and its many years of environmental conservation activities. In the ECO FACTORY certification examination, they were evaluated on the contents of their initiatives involving conserving resources, saving energy, protecting water resources, reducing greenhouse gases, green procurement, biodiversity, managing emitted gases, waste, wastewater, drugs and hazardous substances, safety and hygiene, logistics, and green spaces within the factory, and contributions to the local community. The certification is valid for three years, and when it is renewed, the examination will check for improvements in the environmental effects of the evaluation items.

Chemical Management

The Shindengen Group is committed to appropriately managing chemicals that are used in the manufacturing process and contained within its products and has established the “promotion of chemical substance management” as part of its environmental policy.

The Chemical Substance Management Committee (consisting of Shindengen’s Asaka Office and domestic Group companies) regularly shares with Group companies the latest information regarding domestic and international laws and regulations, studies green procurement standards, manages information about chemicals contained in products, and manages chemicals used in-house.