- TOP

- About Shindengen

- A Closer Look

Smaller supplies.Greater possibilities.

Products everywhere are becoming thinner, lighter, and more efficient. PCs and smartphones now pack more power-efficient performance into smaller forms. The technological development of power supplies makes it all possible—because no matter how small our products become, power supplies’ circuits and batteries take up the majority of a product’s overall volume and weight.True innovation happens when the power supplies become smaller and lighter, improving power conversion efficiency and reducing the environmental impact in the process. The sooner we innovate power supplies, the sooner we realize the dream products of the future.

True innovation starts with power supplies.

Innovating power supplies makes product innovation possible. Batteries become more efficient, longer-lasting, smaller, lighter, and quieter. New products become more compact and easier to use. A power efficiency improvement of just 1% can expand a product’s potential beyond imagination.

Experts in power supply technology.

Some customers need a compact power supply with big power, while others need larger capacities with less electricity usage. As experts in power supply technology, we realize these demands by leveraging all the technology at our disposal: high-precision control design, circuitry layouts, materials, and micro-fabrication. We use everything we have to optimize potential, creating new possibilities for power supply technology and our customers.

Trusted everywhere we operate.

Shindengen’s 14 domestic and 16 international bases make us a truly global company, with overseas sales accounting for more than 60% of total sales. We boast the world’s top share of the regulator market for motorcycles, which is mainly popular in Asia. We also have a top share of bridge diodes, one of the most-used power semiconductors in home appliances.

About Shindengen

Shindengen Electric Manufacturing Co., Ltd.

Established: August 16,1949

Main Business:

Manufacturing and sales of electric products

Head Quater:Ohtemachi,Chiyoda-ku,Tokyo,Japan

Three core technologies,

developed from the start.

Our history goes back to power supply products we developed for telephone switching stations and other large equipment in the 1950s. In the 1970s, Shindengen began full-scale development of automotive electrical components for motorcycles and grew alongside the power semiconductor industry.

Now, Shindengen is one of the few manufacturers making all three core technologies necessary for power supplies: power semiconductor manufacturing, circuit design technology, and system mounting technology for in-vehicle electrical components , and other products. These core technologies combine to streamline and optimize the entire power supply manufacturing process, making Shindengen unparalleled in the industry.

Power semiconductors,

an evolving industry

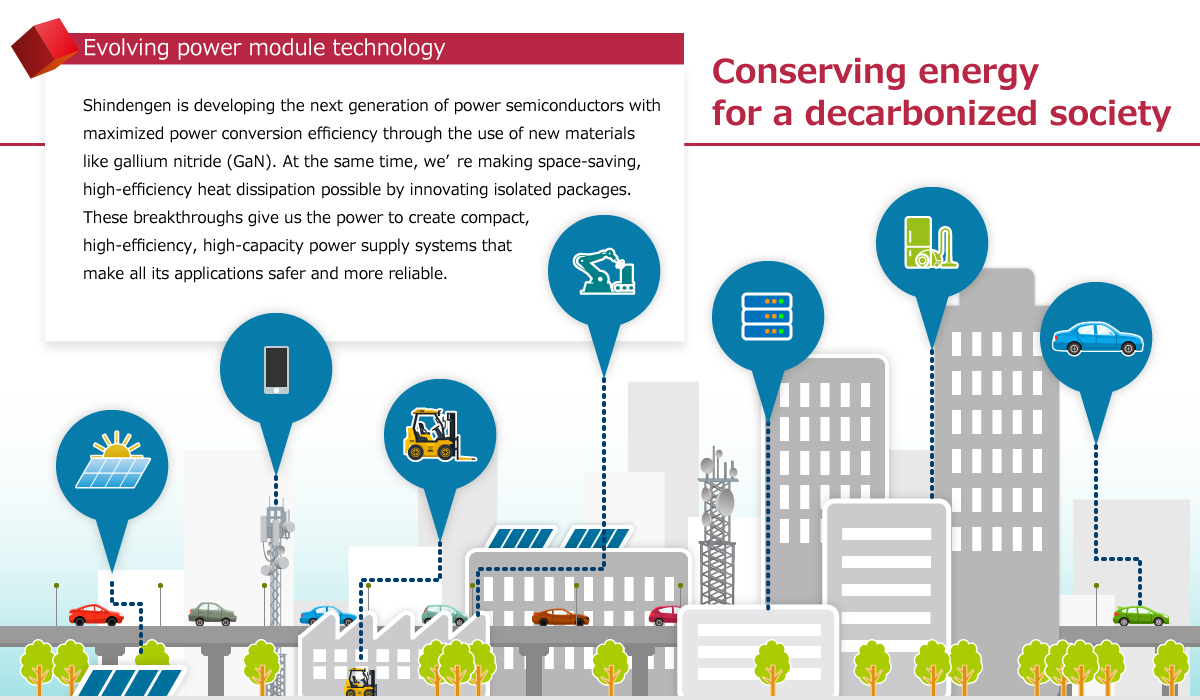

Shindengen’s multi-application power devices can withstand high voltages and large currents while maintaining faster control speeds that improve performance and save energy.

What’s inside a power semiconductor?

Diodes and transistors are the basic components that make up an electronic circuit used in semiconductors. A diode is a reverse current prevention element, and a transistor is a switch element.

A semiconductor’s structure consists of ultra-fine molecules, but power semiconductors handle high voltages and large currents. They must stop high energy with the instantaneous force of a few nanoseconds and withstand decades of continuous use on a semipermanent basis. A vast number of small innovations have made it possible for power semiconductors to handle such high density and high speed operations.

Technology trusted for all applications.

Shindengen’s power supply technology has wide applications in a variety of fields. For example, strictly controlled clean rooms used in semiconductor manufacturing facilities require ultra-high-density, liquid-cooled, customized power supplies to maintain the necessary quality, purity, and noise level standards. Additionally, the power supply technology used in motorcycle regulators require a mechanical design that can withstand high temperatures since excess power converts into heat. Shindengen provides reliable, customized power supplies for any application while improving the performance of the end product.

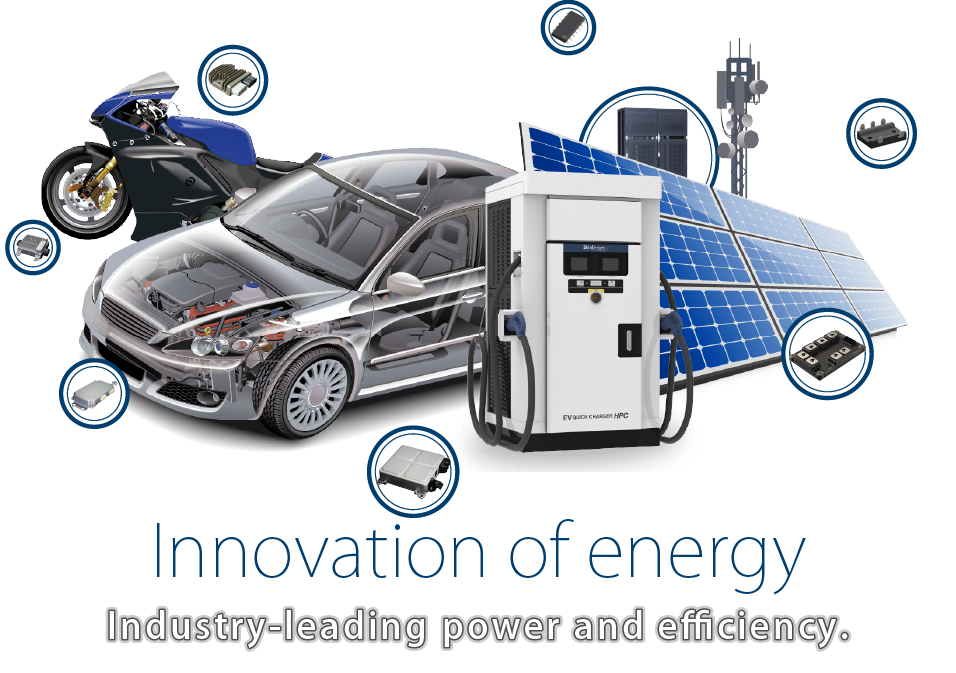

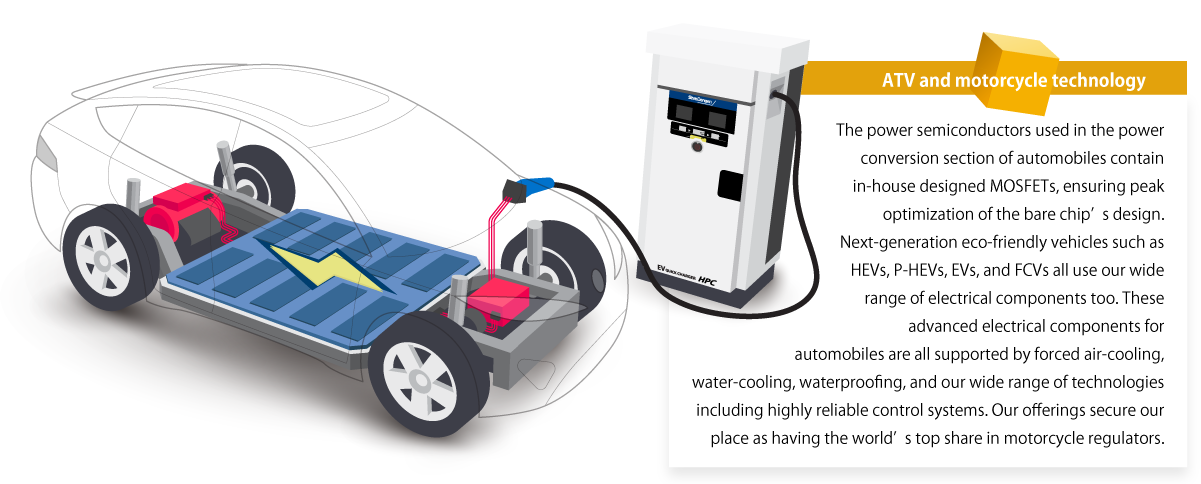

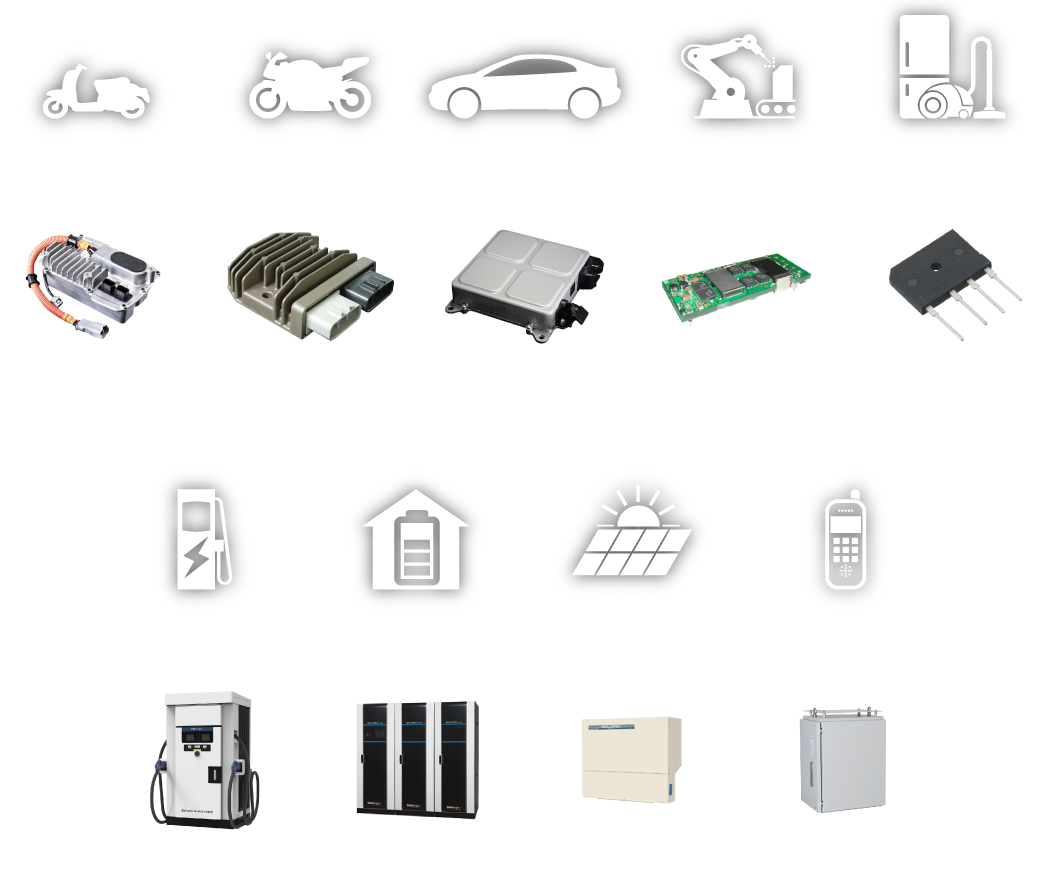

Advanced car electronics

combine Shindengen technologies.

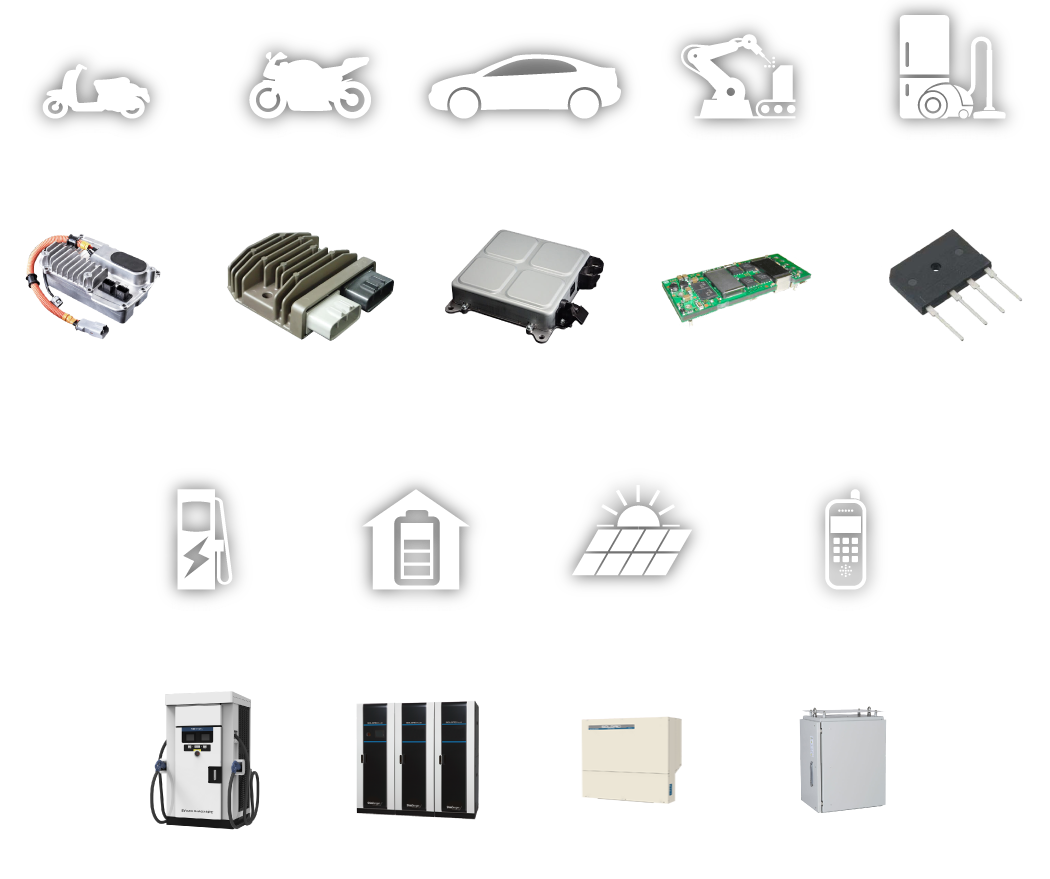

Developing a wide variety of electrical components

We started developing power management electronics when we first designed a selenium rectifier for motorcycles in 1953. Since then, we’ve focused on the development and sales of regulators, rectifiers, and CDIs (capacitor discharge igniters) for motorcycles. Technology keeps moving forward and so do we—we’ve since expanded our development to include general purpose engine transistor-magnets, engine generator AVRs, governor devices, and more.

We also stay active in the field of environmentally-friendly products by mass producing high-efficiency step-down DC/DC converters for HEVs and FCEVs, and developing ECUs (engine control units) for idle reduction in motorcycles.

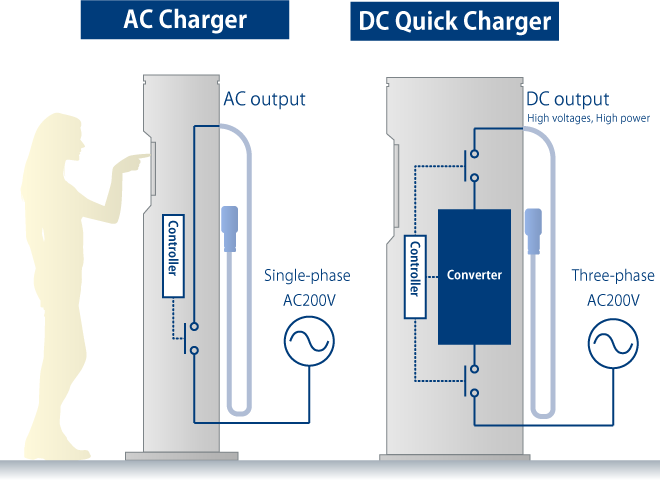

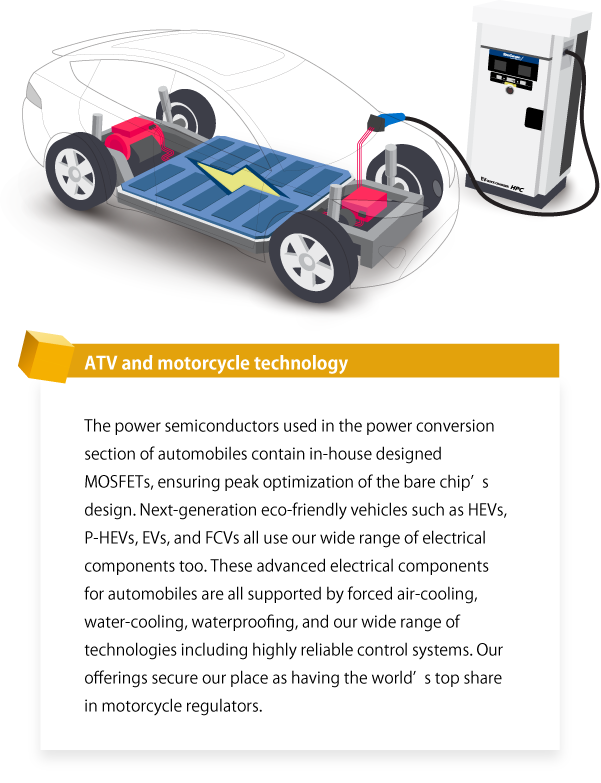

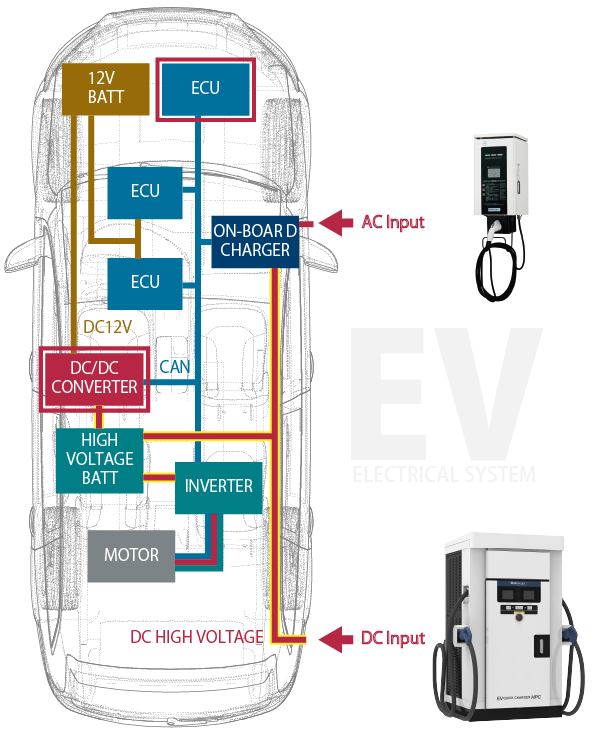

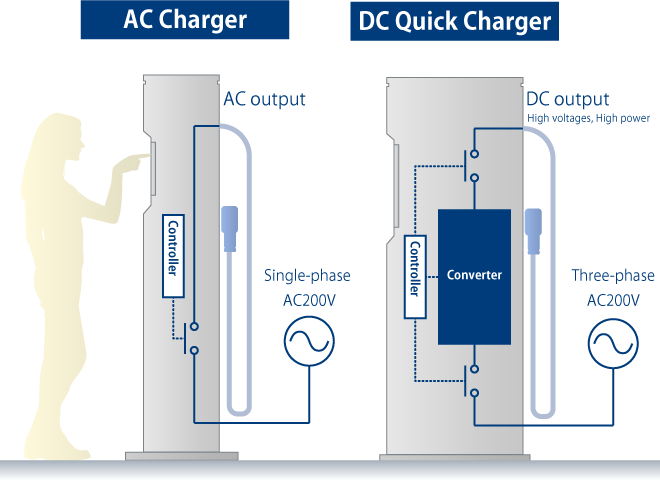

Charging infrastructure for electric vehicles

Charging stations for electric vehicles are essential as more people make the switch from gasoline. Shindengen is one of the few manufacturers developing both regular chargers and fast chargers for public spaces, Fast chargers, or “DC quick chargers,” charge batteries dozens of times faster than home power outlets. We’ll continue to increase charging capacity according to the CHAdeMO standard in Japan for fast charging output, which determines the speed of EV charging. We also offer an after-sales service including maintenance and technical support to increase the value of our offerings.

Environmentally-friendly

energy utilization

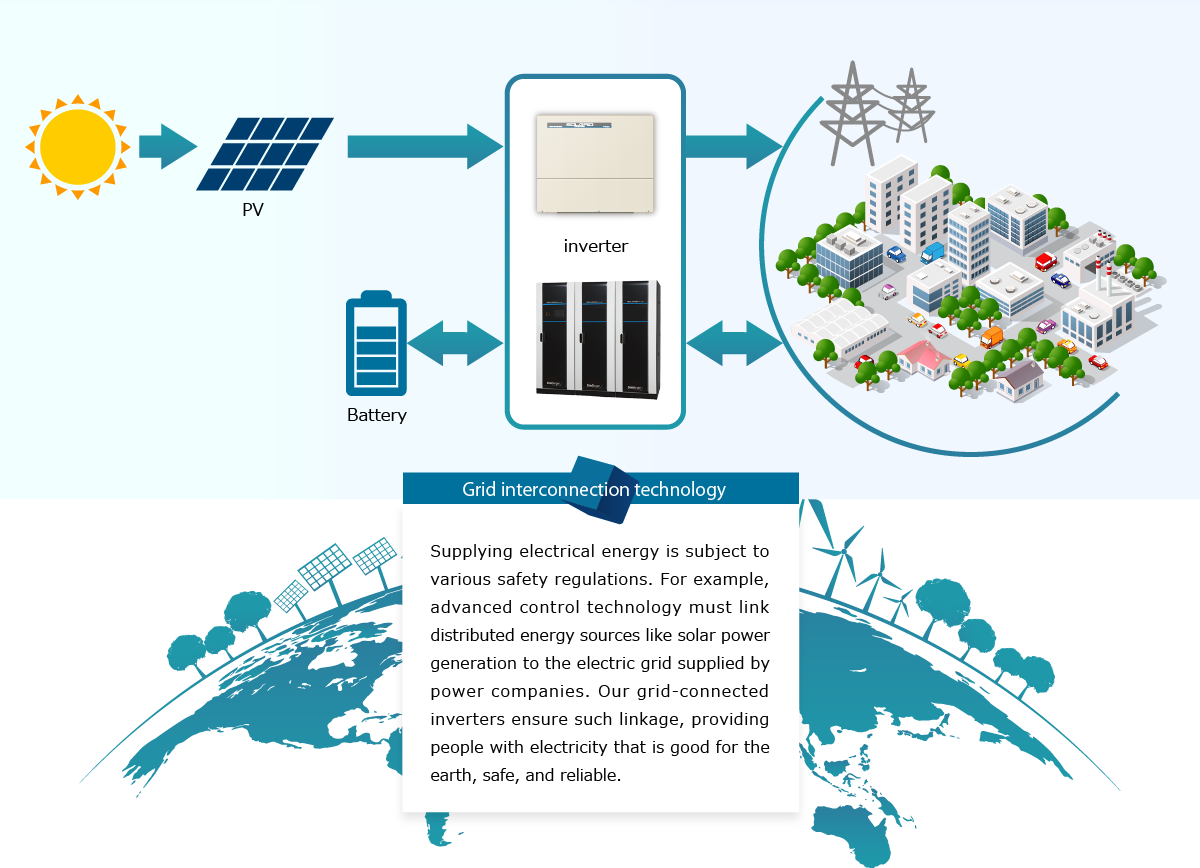

Environmental and energy initiatives

Renewable energy systems also use Shindengen’s technology. To harness renewable energy, direct current electricity generated by solar power must be converted into the alternating current electricity we use in our daily lives. Shindengen’s grid-connected inverters are power supply devices that play an important role in utilizing these forms of clean, renewable energy.

Products made with people in mind

We consider all aspects beyond performance in our product development. That means assessing ease of use and the full product experience too. Our controllers with Japanese-language LCD panels developed for the Japanese market do more than take over difficult operations for the users. They measure ambient sound with precise noise level devices and testing by human ears to make living spaces calmer and quieter. Seeing, hearing, and touching—Shindengen maintains uncompromising attention to detail when developing its entire product lineup.

Supporting data communications

with reliable power supply infrastructure

Shindengen’s power supply technology supports the information networks indispensable to our lives today, including cell phone base stations and data centers.

Growing alongside technology

Shindengen’s power supplies began with selenium rectifiers manufactured for early telephone switching systems in 1952. Since then, we’ve grown as a company offering reliable power devices and power supply technology. Our germanium and silicon semiconductor technology was the first in the industry used for rectification applications.

Power supply that never sleeps

Reliability is one of the most important requirements for power supply systems in cell phone base stations, switching stations, and data centers. Even in the event of a system failure, our backup systems switch on instantly to provide time for maintenance and replacement without stopping communication. Shindengen’s power supply systems operate 24 hours a day, 7 days a week in an increasingly sophisticated information network. That’s true reliability.

Smaller supplies.

Greater possibilities.

Products everywhere are becoming thinner, lighter, and more efficient. PCs and smartphones now pack more power-efficient performance into smaller forms. The technological development of power supplies makes it all possible—because no matter how small our products become, power supplies’ circuits and batteries take up the majority of a product’s overall volume and weight. True innovation happens when the power supplies become smaller and lighter, improving power conversion efficiency and reducing the environmental impact in the process. The sooner we innovate power supplies, the sooner we realize the dream products of the future.

True innovation starts with power supplies.

Innovating power supplies makes product innovation possible. Batteries become more efficient, longer-lasting, smaller, lighter, and quieter. New products become more compact and easier to use. A power efficiency improvement of just 1% can expand a product’s potential beyond imagination.

True innovation starts with power supplies.

Innovating power supplies makes product innovation possible. Batteries become more efficient, longer-lasting, smaller, lighter, and quieter. New products become more compact and easier to use. A power efficiency improvement of just 1% can expand a product’s potential beyond imagination.

About Shindengen

Shindengen Electric Manufacturing Co., Ltd.

Established: August 16,1949

Main Business:

Manufacturing and sales of electric products

Head Quater:Ohtemachi,Chiyoda-ku,Tokyo,Japan

Trusted everywhere we operate.

Shindengen’s 14 domestic and 16 international bases make us a truly global company, with overseas sales accounting for more than 60% of total sales. We boast the world’s top share of the regulator market for motorcycles, which is mainly popular in Asia. We also have a top share of bridge diodes, one of the most-used power semiconductors in home appliances.

Three core technologies,

developed from the start.

Three core technologies, developed from the start.

Our history goes back to power supply products we developed for telephone switching stations and other large equipment in the 1950s. In the 1970s, Shindengen began full-scale development of automotive electrical components for motorcycles and grew alongside the power semiconductor industry.

Now, Shindengen is one of the few manufacturers making all three core technologies necessary for power supplies: power semiconductor manufacturing, circuit design technology, and system mounting technology for in-vehicle electrical components and other products. These core technologies combine to streamline and optimize the entire power supply manufacturing process, making Shindengen unparalleled in the industry.

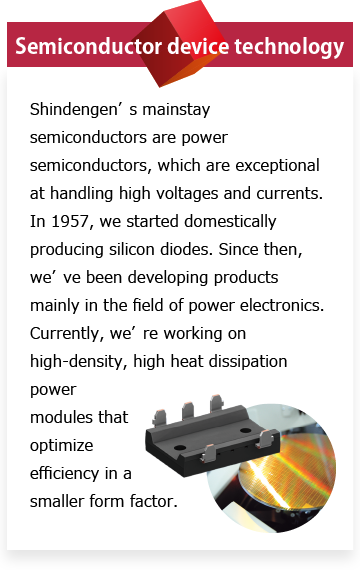

Power semiconductors,

an evolving industry

Shindengen’s multi-application power devices can withstand high voltages and large currents while maintaining faster control speeds that improve performance and save energy.

What’s inside a power semiconductor?

Diodes and transistors are the basic components that make up an electronic circuit used in semiconductors. A diode is a reverse current prevention element, and a transistor is a switch element.

A semiconductor’s structure consists of ultra-fine molecules, but power semiconductors handle high voltages and large currents. They must stop high energy with the instantaneous force of a few nanoseconds and withstand decades of continuous use on a semipermanent basis. A vast number of small innovations have made it possible for power semiconductors to handle such high density and high speed operations.

Technology trusted for all applications.

Shindengen’s power supply technology has wide applications in a variety of fields. For example, strictly controlled clean rooms used in semiconductor manufacturing facilities require ultra-high-density, liquid-cooled, customized power supplies to maintain the necessary quality, purity, and noise level standards. Additionally, the power supply technology used in motorcycle regulators require a mechanical design that can withstand high temperatures since excess power converts into heat. Shindengen provides reliable, customized power supplies for any application while improving the performance of the end product.

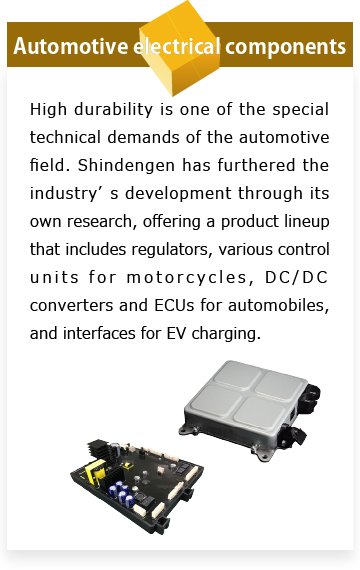

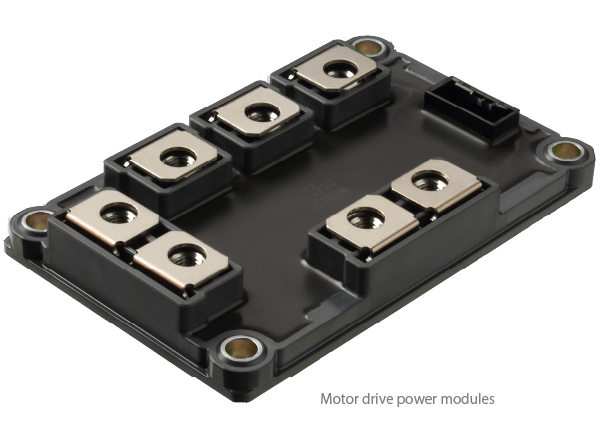

Advanced car electronics combine Shindengen technologies

Developing a wide variety of electrical components

We started developing power management electronics when we first designed a selenium rectifier for motorcycles in 1953. Since then, we’ve focused on the development and sales of regulators, rectifiers, and CDIs (capacitor discharge igniters) for motorcycles. Technology keeps moving forward and so do we—we’ve since expanded our development to include general purpose engine transistor-magnets, engine generator AVRs, governor devices, and more.

We also stay active in the field of environmentally-friendly products by mass producing high-efficiency step-down DC/DC converters for HEVs and FCEVs, and developing ECUs (engine control units) for idle reductio in motorcycles.

Charging infrastructure for electric vehicles

Charging stations for electric vehicles are essential as more people make the switch from gasoline. Shindengen is one of the few manufacturers developing both regular chargers and fast chargers for public spaces, Fast chargers, or “DC quick chargers,” charge batteries dozens of times faster than home power outlets. We’ll continue to increase charging capacity according to the CHAdeMO standard in Japan for fast charging output, which determines the speed of EV charging. We also offer an after-sales service including maintenance and technical support to increase the value of our offerings.

Environmentally-friendly energy utilization

Environmental and energy initiatives

Renewable energy systems also use Shindengen’s technology. To harness renewable energy, direct current electricity generated by solar power must be converted into the alternating current electricity we use in our daily lives. Shindengen’s grid-connected inverters are power supply devices that play an important role in utilizing these forms of clean, renewable energy.

Products made with people in mind

We consider all aspects beyond performance in our product development. That means assessing ease of use and the full product experience too. Our controllers with Japanese-language LCD panels developed for the Japanese market do more than take over difficult operations for the users. They measure ambient sound with precise noise level devices and testing by human ears to make living spaces calmer and quieter. Seeing, hearing, and touching—Shindengen maintains uncompromising attention to detail when developing its entire product lineup.

Supporting data communications with reliable power supply infrastructure

Shindengen’s power supply technology supports the information networks indispensable to our lives today, including cell phone base stations and data centers.

Growing alongside technology

Shindengen’s power supplies began with selenium rectifiers manufactured for early telephone switching systems in 1952. Since then, we’ve grown as a company offering reliable power devices and power supply technology. Our germanium and silicon semiconductor technology was the first in the industry used for rectification applications.

Power supply that never sleeps

Reliability is one of the most important requirements for power supply systems in cell phone base stations, switching stations, and data centers. Even in the event of a system failure, our backup systems switch on instantly to provide time for maintenance and replacement without stopping communication. Shindengen’s power supply systems operate 24 hours a day, 7 days a week in an increasingly sophisticated information network. That’s true reliability.

- Please note that the information contained in releases is current as of the date of press announcement (Jan,2021), but may be subject to change without prior notice.