- TOP

- Lineup

- Our Product Story

- Large current capacity achieved in a 5S package! D35XB80

Large current capacity achieved in a 5S package! D35XB80

The theme for this edition is the shift to larger current for the 5S packages which are Shindengen's leading semiconductor package. The D35XB80 is a new product created by revising the conventional 5S package structure and achieving a larger current capacity. The engineers and salespeople involved in development look back at the difficulties and joys they experienced and talk about product characteristics and Shindengen's package technologies.

(Left)

Takayuki Kubo

Sales Div. Group

Joined Shindengen in 1995.Mr. Kubo is responsible for customers in a variety of industries, with a focus on the home electronics and automotive markets.

(Right)

Toshikazu Arai

Electronic Device Div. Group Assistant Specialist

Joined Shindengen in 1997. Mr. Arai works on development of discrete semiconductors with a focus on diodes and thyristors.

Contents

Changing needs of the times and 5S packages

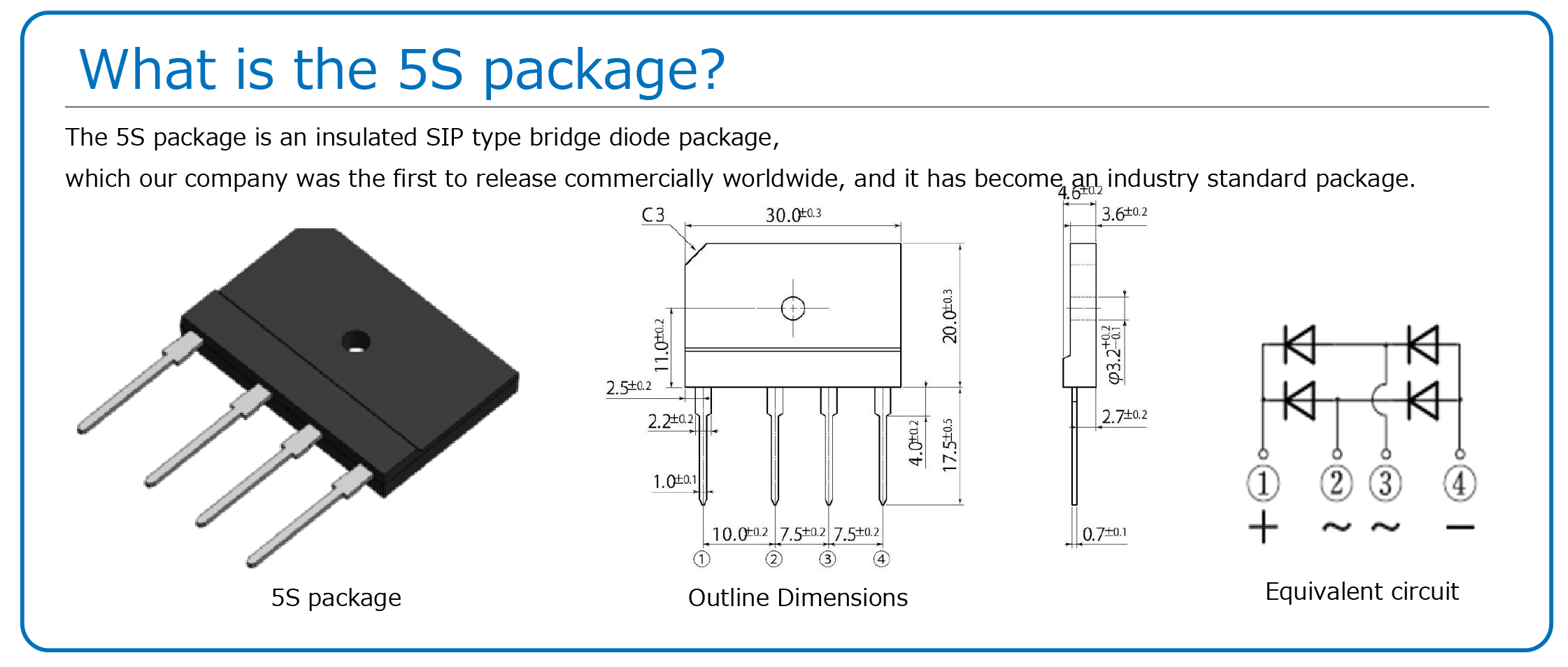

The world's first 5S package was developed by Shindengen Electric Manufacturing Co., Ltd. and has since had a long history in the semiconductor industry.

When it was first developed, the 5S was an original Shindengen package, however it proved extremely popular, especially among white goods home electronics manufacturers, and has since grown into a global standard package. The 5S package is a major contributing factor to the strong correlation of bridge diodes with Shindengen in the semiconductor industry.

The 5S package had an output of 5A during early development in the 1980's, however subsequent technological developments have made it possible to achieve up to 25A while maintaining the same internal structure. However, the recent shift towards higher functionality and added functionality in home electronics, industrial equipment, and nearly all end products has also resulted in greater needs for higher power. This means that there is demand for even higher power in 5S packages as well.

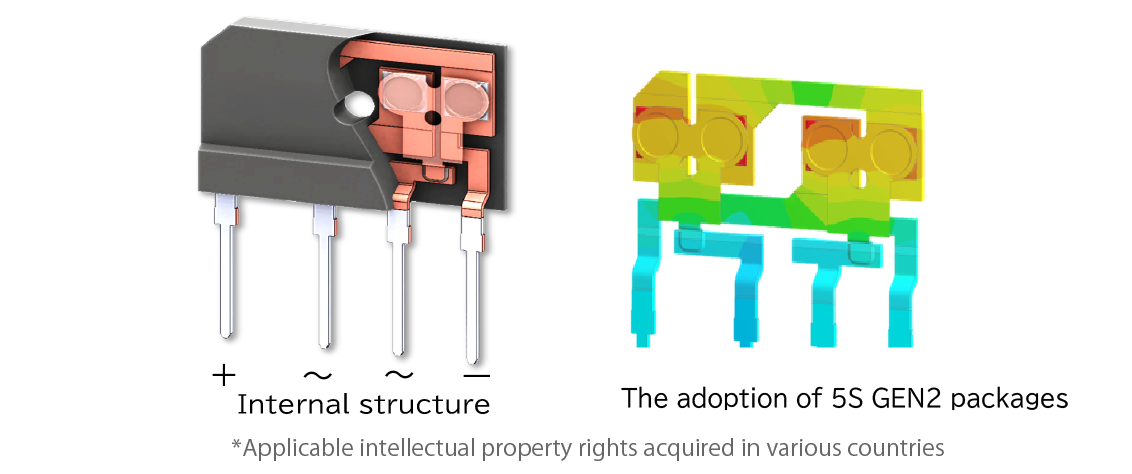

Now, approximately 35 years after initial development, Shindengen has developed the new "5S GEN2" internal structure in order to achieve higher power of 25A and higher. We have also successfully produced the new D35XB80 product which incorporates this new structure.

Let's take a look at what events lead to the development and what difficulties were faced...

The courage to change! The catalyst was listening to customer opinions.

Kubo:

A customer who I worked with at the time was using bridge diodes from another manufacturer, but the customer struggled with the very poor heat dissipation of those products.

The bridge diodes the customer was using at the time were a large current type with an output current of 25A or higher in a 5S package. There was very little selection of products capable of output of large current at that time, so the customer had little choice but to use those products...

It was under these circumstances that the customer made a request, "Bridge diodes which could output 25A or higher while maintaining the same 5S package external dimensions but with lower heat generation. Since Shindengen is specialized in the manufacture of diodes, would it be possible to make such a product?". I was very happy when they made the request. I felt that they made the request because they had such faith in our company and I wanted to help them solve their issue.

However, in order to develop larger current products which could support 25A or higher, it was necessary to completely revise the internal structure of the 5S package. The 5S package had a long history of use, and making changes to something that had remained unchanged for so long requires a great deal of energy and effort to overcome that inertia. So, gathering the "courage to change", we held talks internally multiple times, slowly gaining understanding and cooperation, until the development of the new "5S GEN2" internal structure was decided upon. It was also decided to commercially develop the new D35XB80 product which would allow for output of 35A, exceeding the previous threshold of 25A output.

Difficulties achieving larger current capacity. Shindengen's technological capabilities applied to ensure quality and resolve issues!

Arai:

If we were to just install a larger chip in the same package, we would be able to achieve larger current capacity. However, if we did that, when that larger current flowed, it would make it easier for the overall package temperature to also increase, causing heat generation issues. The product from a different manufacturer which the customer had been using also had an issue where the temperature of the terminals would rise during operation, causing temperature increases to occur on specific terminals leading to an imbalance in temperature distribution. As a result the overall package temperature would increase and result in extreme temperature imbalances.

In order to increase the heat dissipation of the 5S package and overcome these issues we carried out repeated testing through simulation of over 30 different internal structure patterns. We searched for the most optimal combinations by changing various conditions, such as the lead frame width, the chip layout positions, mold resin thickness, etc., and testing combinations of these changes.

The 5S GEN2 came about as the result of these attempts. This new package type maintains the same 5S external dimensions, while improving heat dissipation to allow for mounting of larger current chips, and greatly increasing the maximum current capacity from the previous 25A to 35A.

If we were able to change the external dimensions, it would not be so difficult to achieve higher current capacities; however this development was based on a request from a customer to achieve this while maintaining the same 5S package external dimensions. There were a lot of limitations to overcome and we had quite a difficult time finally arriving at the optimal internal structure.

All of Shindengen works in unison to meet customer expectations!

Arai:

We finally had a sample ready and when we asked the customer to assess it, they immediately carried out assessment for us. The customer happily reported that, "we had solved the heat generation problem the customer had struggled with when using the other company's products!", which was extremely gratifying.

We also received praise from superiors that we had succeeded in changing something that had remained unchanged for so long, and completed a development which would be sure to become a part of company history, which made the entire experience very memorable. We also received a company award for outstanding technological development. I am very proud that something I designed was able to be incorporated as a variation for packages which have been sold for so long.

Kubo:

Coordinating the customer's mass production schedule and our internal development schedule was very difficult. At first, development was not able to keep up with the schedule which the customer expected. However, we kept repeatedly telling the involved personnel that the customer was placing a lot of faith in and had great expectations of our company, which slowly changed the atmosphere inside the company and helped to generate a sense of togetherness. We were able to respond to each customer inquiry quickly and accurately because of our strong internal cooperation.

Going forward, as a salesperson I would like to continue to dedicate myself to being able to propose better products by being attentive to customer needs and being willing to cooperate. I want to all of Shindengen to work in unison to meet customer expectations!

Mr. Arai and Mr. Kubo talk about the amazing facets of the D35XB80!

POINT 1: Maintaining the industry standard 5S package

Because the external dimensions of the widely adopted and relied upon 5S package remain the same, there is no need to change boards or mounting processes when switching from previous products.

POINT 2: Lead temperatures of 100℃ and lower

(with 25℃ water cooled heat dissipation fins attached at 35A output)

POINT 3: Extremely low temperature variation among terminals

For the 5S GEN2, we achieved for the most optimal combinations by changing various conditions, such as the lead frame width, the chip layout positions, mold resin thickness, etc., and testing combinations of these changes. This allowed us to successfully decrease and equalize terminal temperatures. This will greatly contribute to board mounting reliability for customers.

Editor's postscript

The 5S Package is one of Shindengen's core products. We were able to achieve a significant revision of the structure of the product approximately 35 years after its first development because of our company's wealth of knowledge accumulated across our many years of operation. We then released the D40XB100 with a maximum output of 40A to great response from customers in a wide range of markets.

In addition, Shindengen's Asaka Office began operation from 2021, concentrating the research and development divisions and sales divisions (and staff divisions) into a single location. This integration of manufacturing and sales improved cooperation, and allows us to more quickly and accurately respond to customers. If you have issues with shifting to larger power capacities, heat dissipation, or any other issues, please contact us for a consultation.