- TOP

- Lineup

- Our Product Story

- Realizing great synergy benefits! The TW-77 DC/DC converter

Realizing great synergy benefits! The TW-77 DC/DC converter

(Left)

Koji Wakabayashi

Car Electronics Div. Group Chief Engineer

Joined Shindengen in 2001 Mr. Wakabayashi has over 20 years of experience and achievements as a DC/DC converter circuit designer. He is currently involved in product planning from a management position.

(Right)

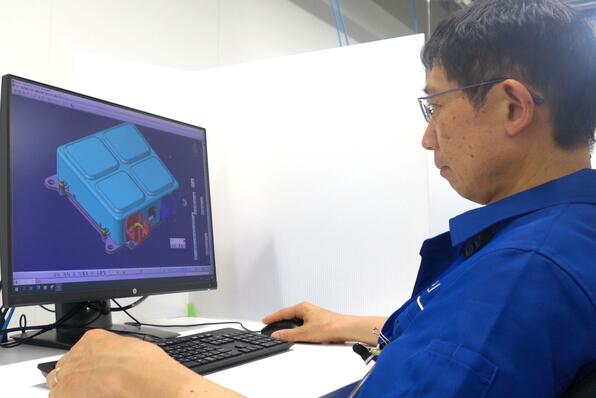

Takuji Yamashiro

Car Electronics Div. Group Senior Engineer

Joined Shindengen in 2007 Mr. Yamashiro has mainly worked on development of DC/DC converters, ECU, and other 4-wheel vehicle products as a structural designer. He is also currently responsible for training newer employees as part of the company design verification meetings by using his wealth of knowledge to point out problems and propose potential improvements, etc.

Approximately 80% of Shindengen's Car Electronics Div. sales come from two-wheel vehicle products. Meanwhile, as the shift away from gasoline vehicles continues to accelerate worldwide, and the development of so-called "environmentally friendly" vehicles such as EV and HEV continues to advance, Shindengen is also working to strengthen our development of automobile components.

The DC/DC converters we are introducing here are a system which converts the high voltage battery power which serves as the energy source for electric motors into low voltage battery power. They are essential products for environmentally friendly vehicles equipped with drive motors, and Shindengen first began mass production of DC/DC converters in 2002.

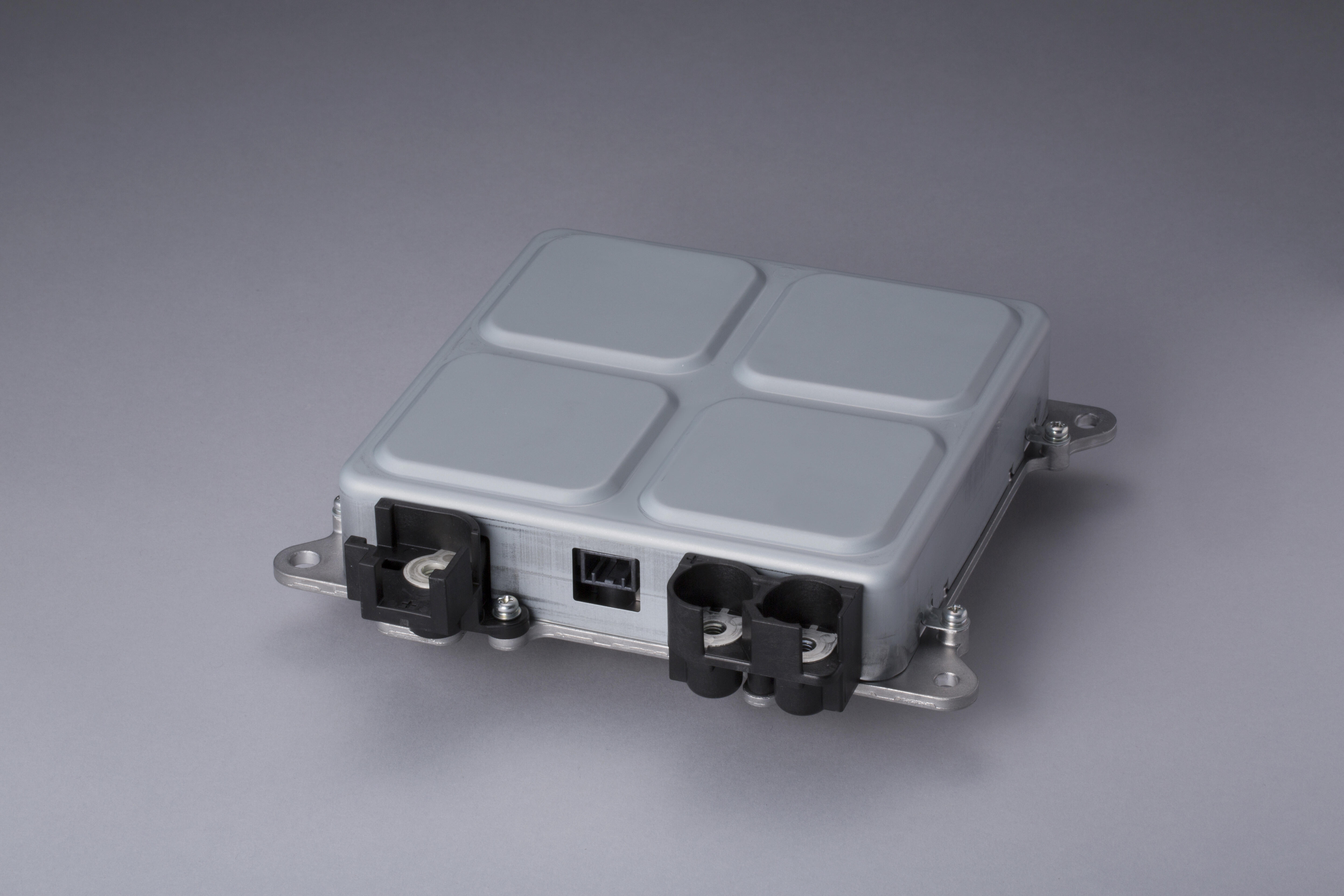

TW-77

Contents

Aiming to provide added value to improve competitiveness

Wakabayashi: Shindengen has developed products for 4-wheeled vehicles since the initial stages of the introduction of hybrid vehicles to the market, however we were not able to significantly expand the business while dealing with strict regulations and cost requirements, and faced with severe competition.

Compared with other companies which already had significant achievements in the field, it was difficult to win against competitor products by simply fulfilling customer specification requirements; so we came up with the idea that if the development of the TW-77 did more than just satisfy specification requirements and could allow us to provide proposals for even more compact products, it would enable us to offer added value. In order to realize this concept, we started a development project which also involved other departments at Shindengen, including the Electronic Device Div. Group, which develops power semiconductors, and the Magnetic Part Dept., which develops transformers.

Yamashiro: Specifications required by customers were for a volume of 1.45 l, however we proposed a further 30% reduction in external dimensions and a 30% reduction in weight compared to conventional products.

We believed that if we could achieve this size for the product, it would be a highly competitive product that no other company could match. In order to achieve downsizing, it was necessary to improve the heat dissipation of power supply circuit components which tend to generate a lot of heat, which led to the development of custom components mainly consisting of transformers and power semiconductors.

Promotion of development by integrating coil technologies from the Magnetic Part Dept.

Yamashiro: For the development of the transformers, we radically revised the convention structure to improve heat dissipation, and ended up adopting an insert structure with coils coated in resin.

Joint development was carried out with the Magnetic Part Dept., however for the insert resin molded transformers there were issues that differed from those faced with normal transformers, such as insufficient insulation in the resin molded parts. In order to resolve these issues, we searched for a resin manufacturer who had a high level of forming technologies and knowhow related to resin flow analysis, and this allowed us to solve the issue of insufficient resin which was the cause of the insufficient insulation issue. On the advice of the Magnetic Part Dept., we also added a test that allowed us to verify internal insulation, which contributed to improvement of the quality of mass production.

For the transformer structure, the development of the insert resin molding meant starting development from scratch, but the Magnetic Part Dept., which was very familiar with transformers, the Car Electronics Div. Group, and the resin mold manufacturer discussed the issues from differing viewpoints, and worked together to make improvements, which made it possible to achieve a transformer that was the same size as conventional transformers but with 1.7 times the output current, greatly contributing to product downsizing.

In-house development of a power module to achieve downsizing

Wakabayashi: The main FET and rectification FET were composed of discrete components in conventional products, however this required a certain amount of mounting area in order to disperse heat. In order to achieve downsizing, it would be necessary to change something, and it was essential to create a power module with integrated functions. So we approached the Power Module Dept. to have them develop dedicated components which would satisfy our requirements.

The power module required by the Car Electronics Div. Group was in a capacity range which the Power Module Dept. at the time did not have much development experience with, so development was carried out through trial and error. Verification was carried out through simulations multiple times, however when we attempted to create a prototype, we found issues we had not anticipated, so we ended up having to go back to square one multiple times even though we thought we were making progress. However, the customer had a fixed development schedule, and we could not keep them waiting. So we continued carrying out development while readjusting the schedule day-to-day.

Yamashiro: The Car Electronics Div. Group and Power Module Dept. held repeated discussions and testing together aimed at resolving issues, such as installation specifications, in order to confirm feasibility before specifications were finalized.

Wakabayashi: On one occasion, a failure was found during testing which damaged the power module element, and we asked the Power Module Dept. to investigate. The Power Module Dept. was able to analyze the damaged location and identify the cause, while also simultaneously determining what type of countermeasures to put in place. If we had instead procured the component from an external semiconductor manufacturer, we might not have been able to identify the cause.

Finally, completion, after a great deal of effort

We were able to create a product which achieved the size targets which we set thanks to the various departments at Shindengen working together and combining their skills and technologies across departments to integrate various technologies. We also managed to improve efficiency by over 3% above Shindengen conventional products, and the TW-77 also achieved a maximum conversion efficiency of 95.4% and was set for use in vehicle applications.

Wakabayashi: Without the cooperation of the Magnetic Part Dept. and Power Module Dept., we would have faced many more setbacks during the process and would not have been able to realize "a proposal which exceeded specification requirements". It was a race against time.

Yamashiro: This was a new development, and we faced numerous issues along the way. We had our hands full just dealing with the issues, but on top of that the product also had to be deployed to multiple vehicle types, so we were extremely busy, but were able to successfully complete the development by maintaining a "never give up attitude" with the members around us, including superiors.

As a result, the product is being deployed to multiple models thanks to its fuel efficiency improvement and greater flexibility in vehicle installation, contributing to increased interior space and better fuel efficiency, and providing added value for automobile users as well in the form of comfort, environmental friendliness, and lower maintenance costs.

-

-

- The latest model TW115

-

This product, which takes advantage of in-house components including power semiconductors and magnetic components, has high heat dissipation, and its compact and lightweight concept, together with its other product specification exceeding benefits, has earned the approval of customers.

Having been recognized for the high performance of the TW-77, Shindengen successfully used the product as an opportunity to cultivate new customers, and has steadily built a record of successes. In 2022, the development of environmentally friendly vehicles increased significantly, and the product has become one of the primary products driving growth for car electronics, nearly doubling year-on-year sales for 4-wheel vehicle car electronics products.

Editor's postscript

The TW-77 was brought to mass production through the integration of the technical capabilities of the Car Electronics Component Div., however, no matter how good of a product is, its development never truly ends, and we must continue to improve upon newly discovered issues for our next development. For the latest model, further refinements have been made in terms of cost, such as automation of the production line, in order to further strength the competitiveness of the product. As the performance required of car electronics components continues to increase, the Car Electronics Component Div. will continue to take on new challenges to ensure Shindengen products are widely used in a carbon neutral society.