Our ESG Management

Environment

The Shindengen Group established the Shindengen Global Environmental Charter in 1992, and has long made addressing environmental issues a key management priority. Going forward, we will give consideration to international initiatives and targets aimed at creating a sustainable world, such as the Paris Agreement and Sustainable Development Goals (SDGs). The Group will strive to create eco-friendly products and reduce the environmental burden caused by its business activities in order to help address such social issues as climate change.

Focus

1. Reducing CO2 Emissions Through Products

The chart below shows the value that the Shindengen Group provided through eco-friendly technologies in fiscal 2020 in terms of the reduction in electricity or fuel consumed during use and the resulting reduction in CO2 emissions.

■Energy-Saving Products

| Product | Power consumption reduction | CO2 emission reduction | |

|---|---|---|---|

|

Power supply IC series | 411.7 million kWh | 186,239 t-CO2 |

|

Rectifiers for communications equipment | 115.0 million kWh | 56,103 t-CO2 |

|

Power conditioners | 69.6 million kWh | 33,972 t-CO2 |

| Product | Gasoline consumption reduction | CO2 emission reduction | |

|

DC/DC converters for four-wheel vehicles | 2,127 kL | 4,934 t-CO2 |

|

Car electronics for motorcycles | 2,127 kL | 4,934 t-CO2 |

* Annual power consumption reduction = (Annual power consumptions of previous product series – Annual power consumptions of new product series) × Annual units sold

* Annual gasoline consumption reduction = (Annual fuel consumption of a gasoline-powered vehicle (gasoline) – annual fuel consumption of a hybrid electric vehicle (gasoline equivalent)) x Vehicles manufactured

Reducing CO2 Emissions from Business Activities

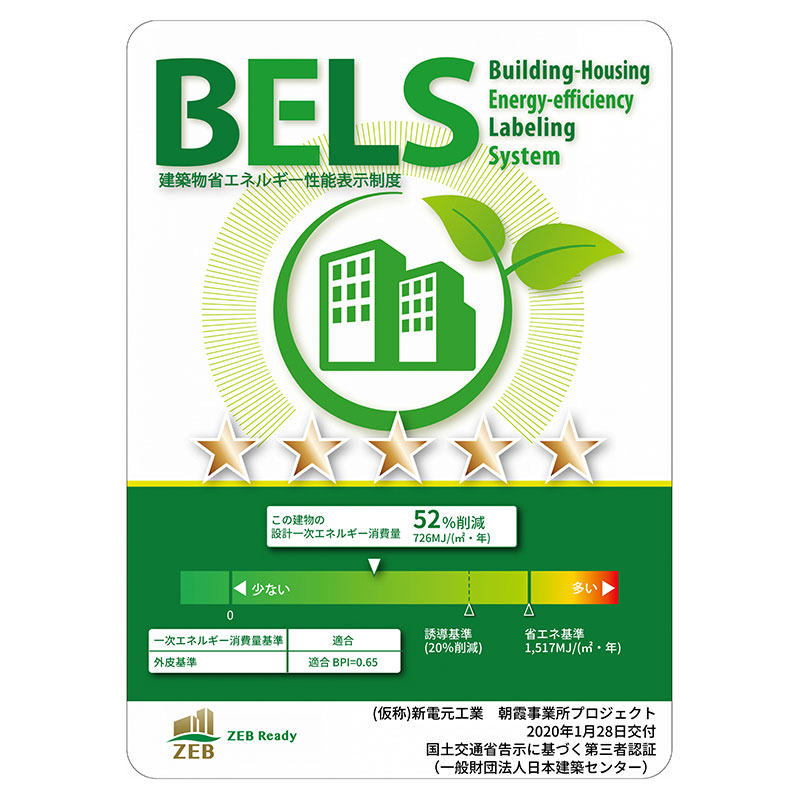

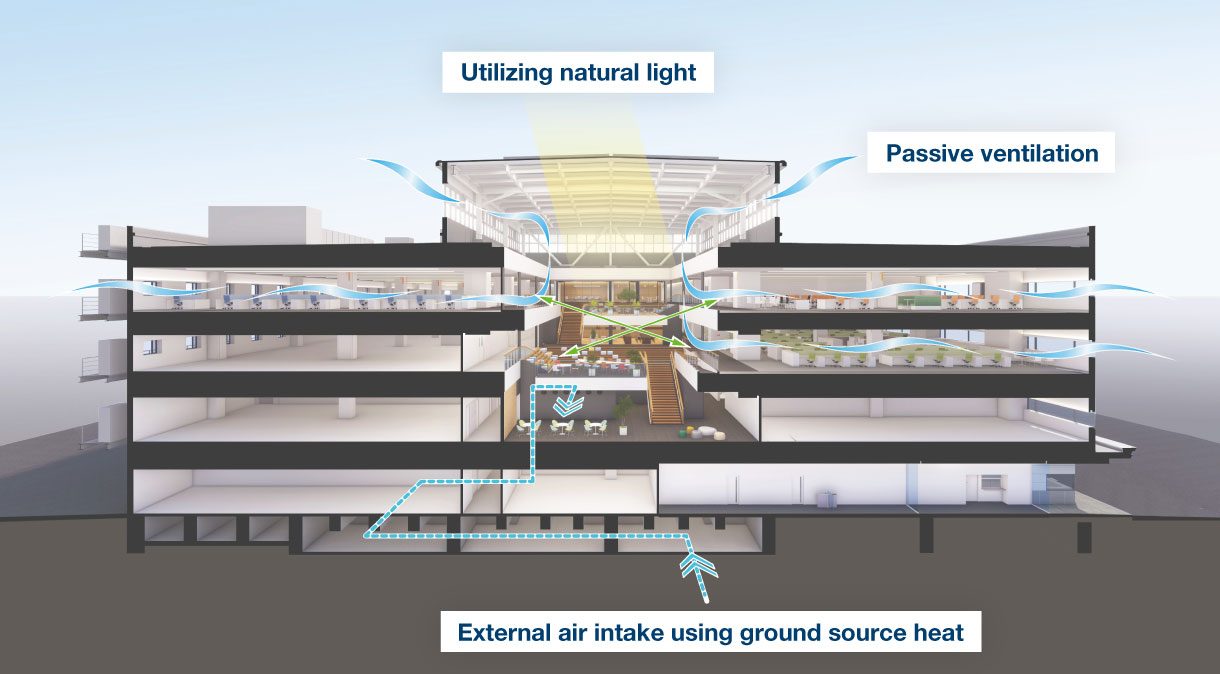

In April 2021, we consolidated functions that were physically separated from one another at the Hanno Factory, including R&D and business operations, and the functions of the Otemachi Head Office, moving them to the newly opened Asaka Office. The Asaka Office is designed to be eco-friendly, as described below. As a result, it has obtained ZEB Ready certification as a building that reduces annual primary energy consumption by 52%.

- Includes an atrium that incorporates natural light and ventilation

- Under-floor air conditioning and heat pump desiccant humidity control outdoor air units

- Proactive use of energy-saving technologies, such as automatic CO2 control

Highlight

CO2 Credits Donated

In support of Saitama Prefecture’s Zero Carbon Saitama initiative, Shindengen donated CO2 credits for 11,482 t-CO2 obtained for the CO2 reduction activities of the Hanno Factory to help Saitama Prefecture meet its emission target. On January 13, 2021, Shindengen received a certificate of gratitude from Saitama Prefecture Governor Motohiro Ono.

We will continue to proactively advance sustainable development in the electronics field for the benefit of humanity and society.